Choosing Between 304 and 316 Stainless Steel? Here’s What You Need to Know

- Emily

- Industry News

304 VS 316 Stainless Steel

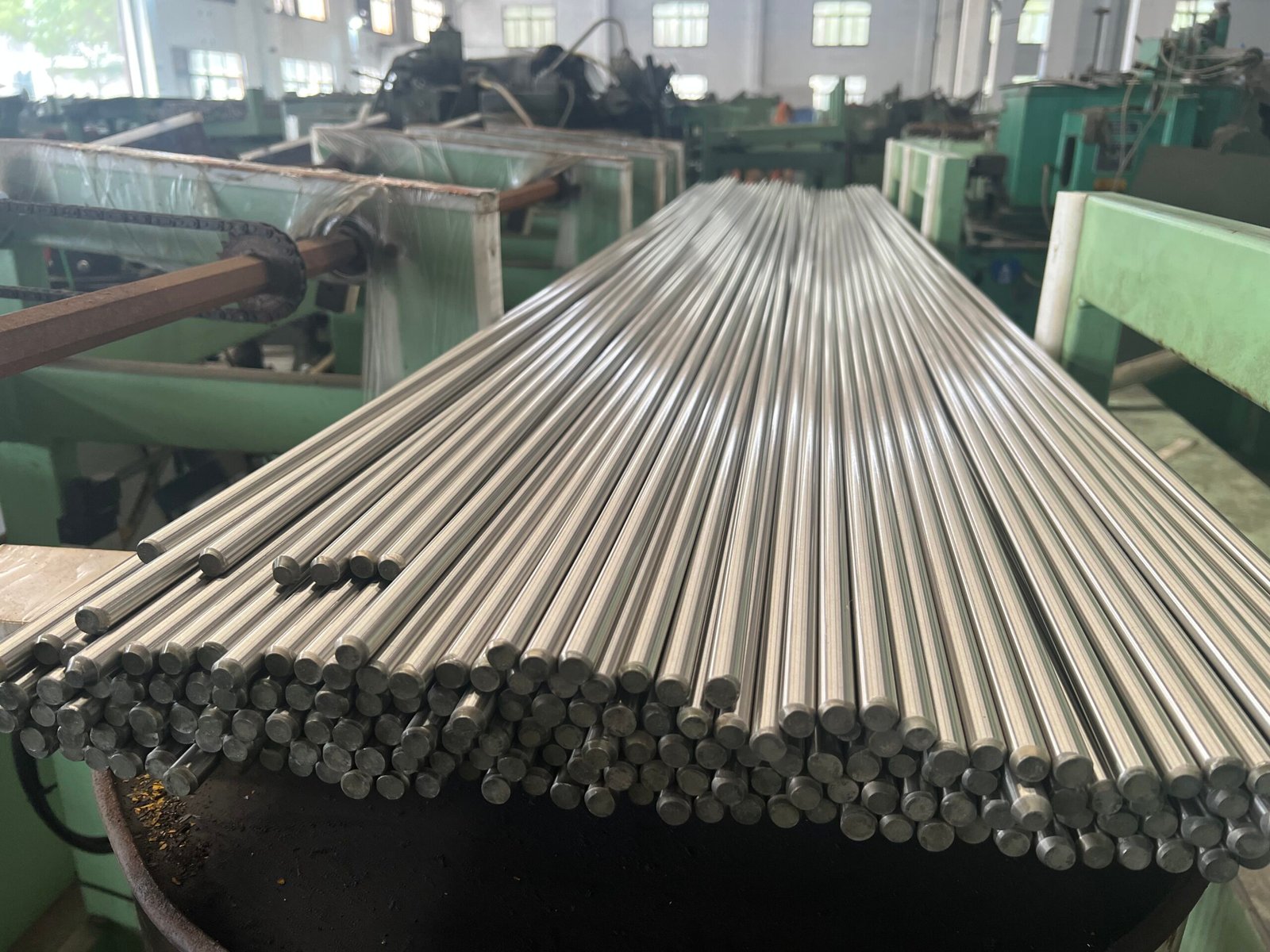

Stainless steel is widely used across various industries due to its durability, corrosion resistance, and aesthetic appeal. Among the most commonly used grades are 304 and 316 stainless steel. While both are austenitic stainless steels and share many similarities, they also have distinct differences that affect their applications. This article outlines the key differences between 304 and 316 stainless steel and their respective uses.

1. Chemical Composition

The primary difference between 304 and 316 stainless steel is their stainless steel chemical composition. Both grades contain iron, chromium, and nickel, but 316 stainless steel includes molybdenum, which enhances its corrosion resistance. Here is a basic comparison:

304 Stainless Steel: Typically contains 18-20% chromium, 8-10.5% nickel, and no molybdenum.

316 Stainless Steel: Typically contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

The addition of molybdenum in 316 stainless steel significantly improves its resistance to pitting and crevice corrosion, especially in chloride-rich environments.

2. Corrosion Resistance

304: Good resistance to oxidation and organic acids but less effective against chlorides (e.g., seawater, de-icing salts).

316: Superior corrosion resistance, especially in chloride-rich or saline environments, due to molybdenum.

3. Strength and Durability

Both 304 and 316 stainless steels have similar mechanical properties, including tensile strength and hardness. However, 316 stainless steel tends to be slightly stronger due to its composition. This makes it more suitable for high-stress environments where additional durability is required.

Temperature Resistance

Both perform well in high temperatures, but 316 maintains strength and corrosion resistance at higher temperatures.

4. Applications

Due to their differences, 304 and 316 stainless steels are used in different applications:

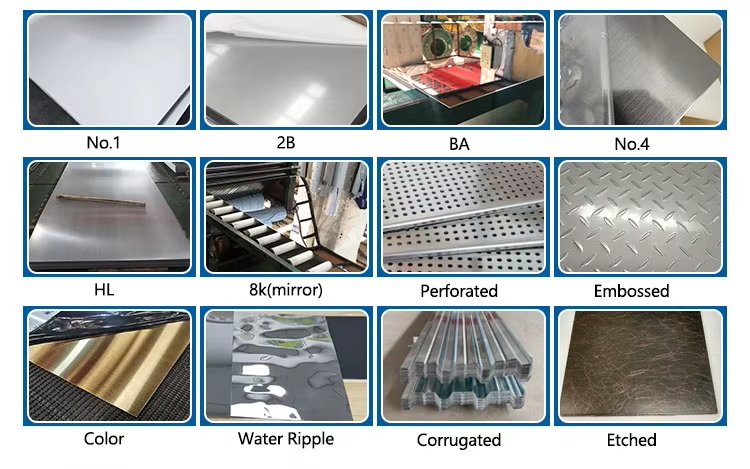

304 Stainless Steel:

Kitchen equipment (sinks, cookware, food processing machinery)

Architectural and decorative applications

Automotive trim and exhaust systems

Industrial equipment

Household appliances

316 Stainless Steel:

Marine applications (boat fittings, offshore structures)

Chemical and pharmaceutical processing equipment

Medical implants and surgical instruments

Food and beverage production (especially in salty or acidic environments)

Heat exchangers and pressure vessels

5. Cost

Stainless steel 304 is more affordable and widely available.

Stainless steel 316 is more expensive due to molybdenum and enhanced properties.

Walmay help you to choose

When choosing between 304 and 316 stainless steel, the decision primarily depends on the environment and application requirements. If corrosion resistance in harsh conditions is crucial, 316 is the better choice. However, if cost is a major factor and the exposure to corrosive elements is minimal, ss 304 provides an excellent balance of performance and affordability. Understanding these differences ensures the right material selection for optimal performance and longevity in various applications.

If you have any inquiry, pls contact us freely sale@rylision.com. Whatsapp:+86 13026184819