Top Stainless Steel Bar Supplier : Round, Square & Flat Bars for All Industries

- Emily

- Industry News

Stainless steel rods are essential materials in various industries due to their excellent corrosion resistance, mechanical strength, and aesthetic appeal. These bars are widely used in construction, manufacturing, chemical processing, automotive, marine, and food industries. Their versatility, combined with the availability of various shapes, grades, and finishes, makes them an indispensable component in both structural and decorative applications.

This article provides a comprehensive overview of stainless steel bars, focusing on their common shapes, frequently used grades, surface treatments, and quality inspection procedures.

1. Shapes of Stainless Steel Bars

Stainless steel bars come in a variety of shapes, each tailored for specific uses and fabrication processes. The most common shapes include round rods, square rods, and flat rods , among others.

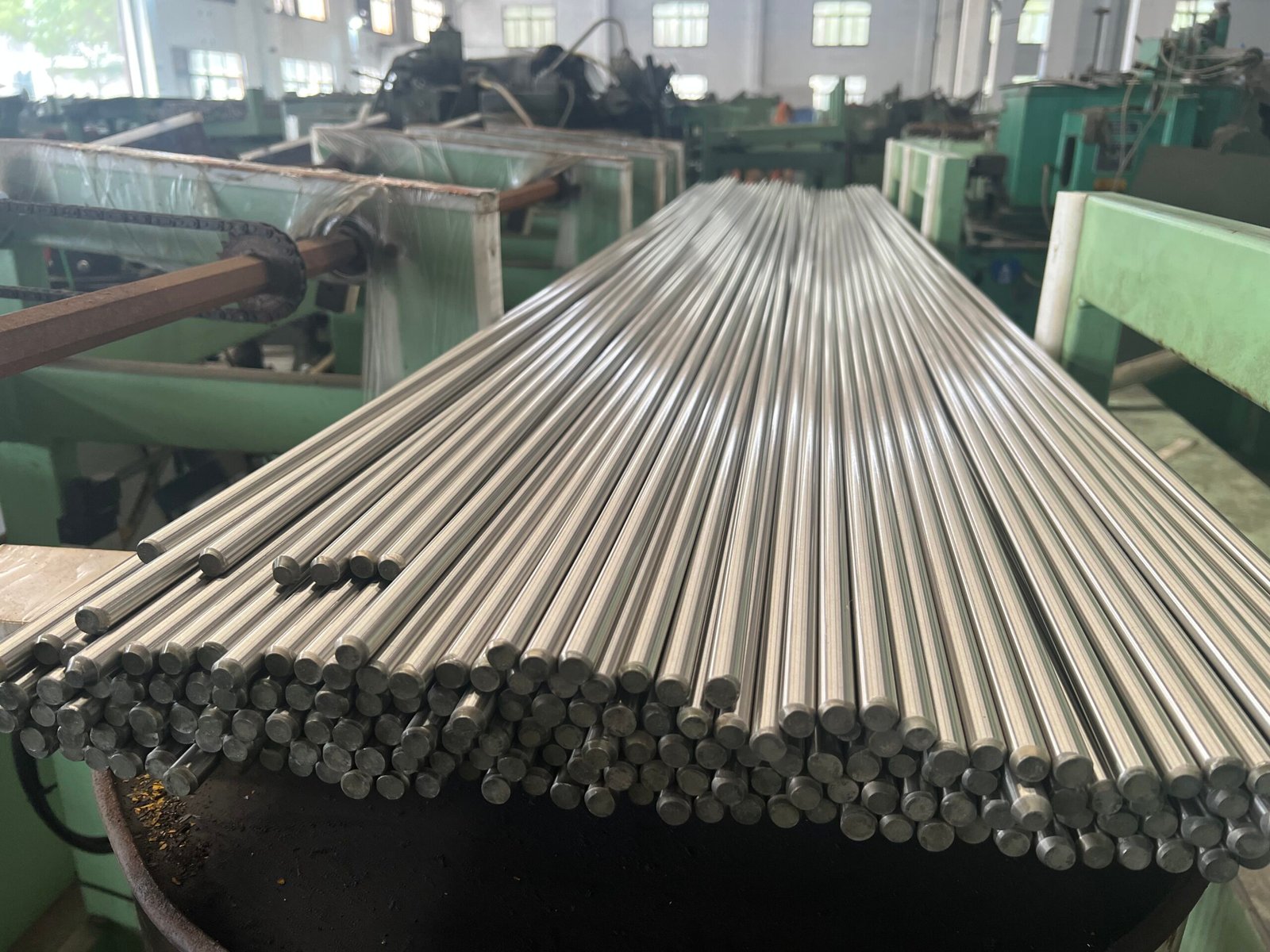

1.1 Round Bars

Round stainless steel bars are the most widely used shape, often employed in the manufacturing of fasteners, shafts, bolts, and valves. The round profile offers excellent strength and is ideal for applications that involve rotational motion. These bars are typically available in diameters ranging from a few millimeters to several inches.

1.2 Square Bars

Square stainless steel bars are primarily used in structural applications and for the manufacture of mechanical parts where even sides are beneficial. Their shape provides higher resistance to twisting and is suitable for ornamental applications as well. Square bars are common in railings, frames, and support structures.

1.3 Flat Bars ( Rectangular Bars)

Flat bars have a rectangular cross-section and are used where a flat surface or support is needed. They are popular in construction, brackets, and fabrication projects. Their versatility also makes them suitable for agricultural implements and industrial tools.

1.4 Other Shapes

Besides the three major types, stainless steel bars can also be manufactured in hexagonal, triangular, or customized profiles. Hexagonal bars are often used in the production of fasteners and machining parts due to their easy grip.

2. Common Stainless Steel Grades

Stainless steel bars are available in different grades, each offering unique properties. The most widely used grades include:

2.1 Austenitic Stainless Steel

Grades: 304, 304L, 316, 316L

Properties: Excellent corrosion resistance, high ductility, and non-magnetic.

Applications: Food processing, chemical industries, marine environments.

2.2 Ferritic Stainless Steel

Grades: 430, 409

Properties: Magnetic, good corrosion resistance, lower cost than austenitic grades.

Applications: Automotive exhaust systems, kitchen equipment.

2.3 Martensitic Stainless Steel

Grades: 410, 420

Properties: High hardness, moderate corrosion resistance, magnetic.

Applications: Cutting tools, valves, pump shafts.

2.4 Duplex Stainless Steel

Grades: 2205 (UNS S31803)

Properties: Combines austenitic and ferritic properties, high strength, excellent corrosion resistance.

Applications: Oil & gas, chemical processing, desalination plants.

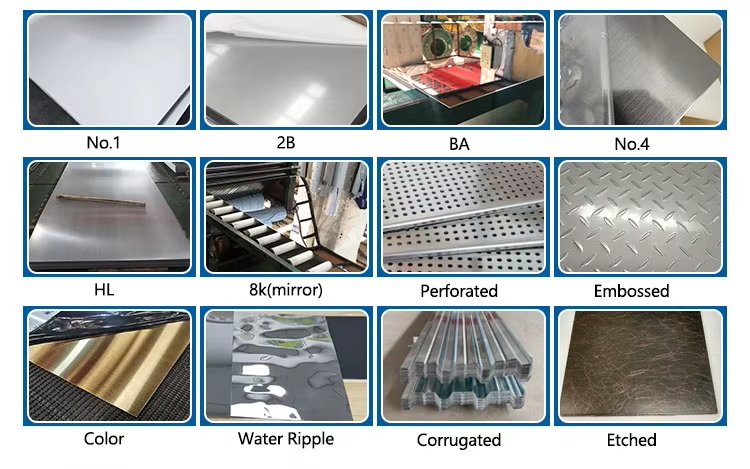

3. Surface Finishes of Stainless Steel Bars

Surface finish is a crucial aspect of stainless steel bar manufacturing, as it affects both the appearance and performance of the product. Various finishes can be applied depending on the intended use, aesthetic requirements, and functional properties.

3.1 Mill Finish

This is the basic finish directly from the rolling mill. It appears rough and dull, often requiring further finishing for applications requiring aesthetics or enhanced corrosion resistance.

3.2 Polished Finish

Polished stainless steel bars have a smooth, reflective surface. They are aesthetically appealing and easy to clean, making them ideal for decorative and sanitary applications. Polishing grades vary from #4 (brushed) to #8 (mirror-like finish).

3.3 Pickled and Passivated

This chemical treatment removes surface impurities, welding scale, and oxidation. The process enhances corrosion resistance and is common in applications requiring high purity, such as pharmaceuticals and food processing.

3.4 Sandblasted or Matte Finish

A matte finish is achieved by blasting the surface with abrasive materials. This provides a uniform, non-reflective surface suitable for architectural and outdoor applications.

4. Quality Inspection of Stainless Steel Bars

Ensuring the quality of stainless steel bars is essential to maintain performance standards and safety in application. Quality inspection involves both visual assessments and mechanical testing.

4.1 Visual Inspection

Surface defects: Inspecting for scratches, pits, cracks, or rust spots.

Dimensional accuracy: Measuring diameters, lengths, and tolerances to confirm compliance with specifications.

4.2 Mechanical Testing

Tensile Testing: Determines yield strength, tensile strength, and elongation.

Hardness Testing: Typically performed using Rockwell or Brinell scales.

Impact Testing: Assesses toughness, especially important in low-temperature applications.

Bend Tests: Ensures ductility and confirms no cracking during bending.

4.3 Chemical Composition Analysis

Spectrometers or X-ray fluorescence (XRF) devices are used to verify that the material composition matches the declared grade. This ensures the alloy contains the correct levels of chromium, nickel, molybdenum, and other elements.

4.4 Non-Destructive Testing (NDT)

Ultrasonic Testing (UT): Detects internal flaws or discontinuities.

Magnetic Particle Testing (for martensitic/ferritic grades): Identifies surface and slightly subsurface defects.

Eddy Current Testing: Suitable for surface and near-surface defect detection without damaging the bar.

Walmay help you to choose

Stainless steel bars, available in a variety of shapes and grades, are foundational elements in numerous industries. Their ability to resist corrosion, maintain strength under extreme conditions, and be shaped or polished for aesthetic purposes makes them an indispensable material.

From round to square to flat profiles, and from common grades like 304 and 316 to specialized duplex varieties, stainless steel bars offer a flexible solution for countless applications. With proper surface treatments and rigorous quality inspections, manufacturers can ensure that these products meet the high expectations of modern engineering and design.

For companies like Rylision, excellence in product quality, consistent supply, and technical support remain critical. Rylision Group offers a wide range of stainless steel bar products, customized to your specifications, with complete documentation, testing reports, and fast delivery. Whether you’re sourcing for structural projects, food-grade installations, or high-performance industrial components, Walmay Group is your trusted partner in stainless steel.

If you have any inquiry, pls contact us freely sale@rylision.com. Whatsapp:+86 13026184819