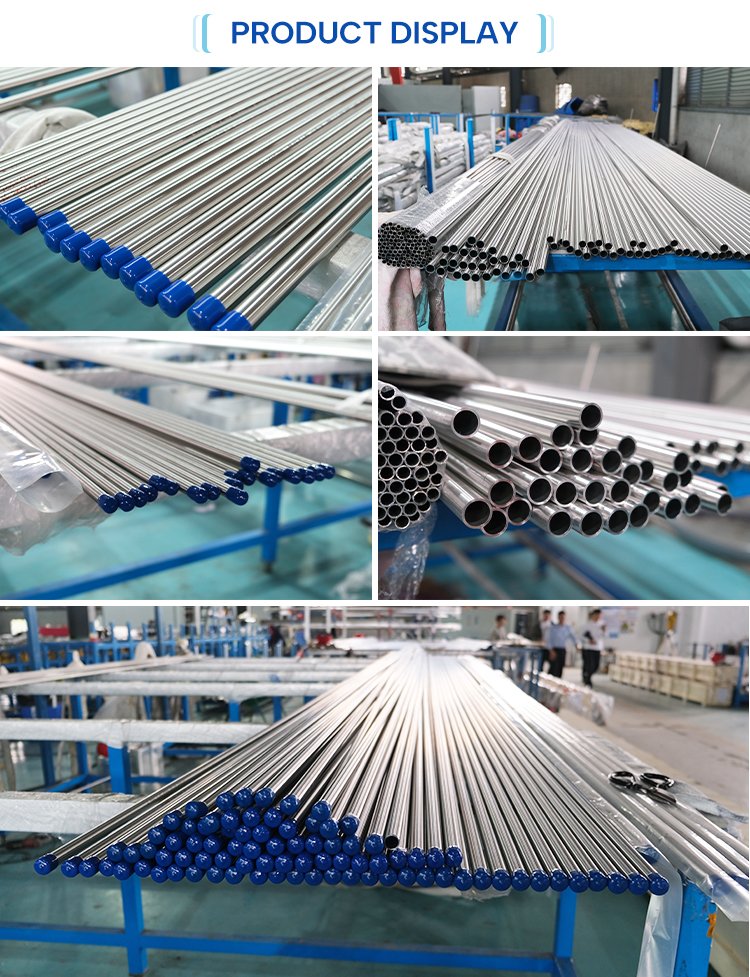

Stainless Steel Bright Annealed (BA) Tube Pipe

- Emily

- Industry News

Stainless steel is one of the most widely used materials in modern industry due to its excellent mechanical properties, corrosion resistance, and aesthetic appeal. Among the various forms and finishes of stainless steel, the BA (Bright Annealed) tube stands out for its superior surface finish and cleanliness, making it a preferred choice in many high-precision and sanitary applications. This article aims to provide a comprehensive overview of stainless steel BA tubes, including their manufacturing process, characteristics, applications, and advantages.

What is a BA Tube?

BA stands for Bright Annealed, which refers to a special type of surface finish achieved through controlled heat treatment in a reducing atmosphere. BA tubes are typically made from austenitic stainless steels such as 304, 304L, 316, and 316L. These tubes undergo a bright annealing process that gives them a highly reflective, mirror-like finish and a smooth, clean surface free from scale or oxidation.

The bright annealing process involves heating the stainless steel tube to a high temperature in a controlled atmosphere, often containing hydrogen or an inert gas, to prevent oxidation. This process not only improves the tube’s surface quality but also enhances its mechanical properties by relieving internal stresses.

Manufacturing Process

The production of stainless steel BA tubes typically follows a series of steps:

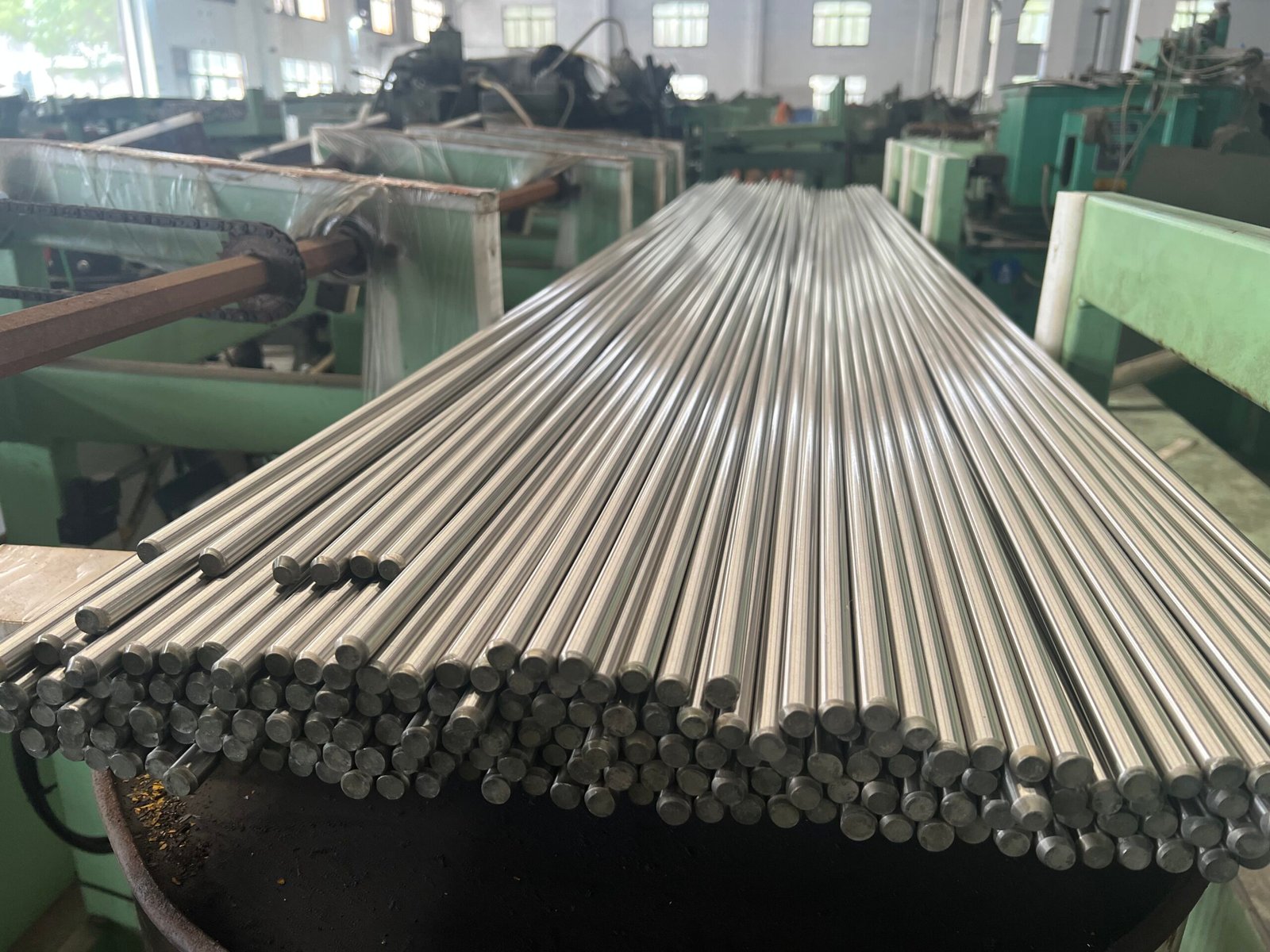

Tube Forming: Stainless steel strips or coils are formed into tubes using welding or seamless extrusion methods.

Cold Drawing: The formed tubes are drawn through dies to achieve precise dimensions and improved surface quality.

Bright Annealing: The cold-worked tubes are annealed in a bright annealing furnace under a reducing atmosphere to achieve the desired surface finish.

Straightening and Cutting: The annealed tubes are straightened and cut to the required lengths.

Cleaning and Inspection: The tubes are cleaned to remove any residual contaminants and are inspected for dimensional accuracy and surface quality.

Key Characteristics

Stainless steel BA tubes exhibit several distinctive features:

Bright, Smooth Surface: The mirror-like finish is not only aesthetically pleasing but also helps in applications requiring high cleanliness.

Excellent Corrosion Resistance: Due to the high chromium and nickel content, BA tubes resist corrosion in a wide range of environments.

Dimensional Precision: The cold drawing and annealing process ensures tight tolerances and consistent wall thickness.

Mechanical Strength: BA tubes retain the inherent strength of stainless steel and offer good formability.

Cleanliness: The bright annealing process minimizes surface contamination, making these tubes suitable for hygienic environments.

Applications of BA Tubes

Thanks to their unique properties, stainless steel BA tubes find use in a wide range of industries, including:

Pharmaceutical and Biotechnology: BA tubes are ideal for cleanroom environments, where contamination must be minimized.

Food and Beverage Processing: The smooth surface prevents bacterial growth and is easy to clean, ensuring food safety.

Semiconductor and Electronics: High purity and cleanliness are essential in these industries, making BA tubes a perfect fit.

Medical Equipment: BA tubes are used in surgical instruments, hospital fixtures, and diagnostic devices.

Automotive and Aerospace: Their strength, corrosion resistance, and appearance make BA tubes suitable for high-performance applications.

Decorative and Architectural: The shiny, mirror-like finish is also valued in aesthetic applications such as handrails, furniture, and building facades.

Advantages of Stainless Steel BA Tubes

Aesthetic Appeal: The reflective surface adds a premium look to any product or structure.

Hygiene: Smooth surfaces reduce the risk of microbial contamination and make cleaning easier.

Durability: BA tubes are resistant to corrosion, chemicals, and wear, ensuring long service life.

Consistency: High dimensional accuracy and uniform finish provide reliability in assembly and performance.

Low Maintenance: Stainless steel requires little maintenance and retains its appearance over time.

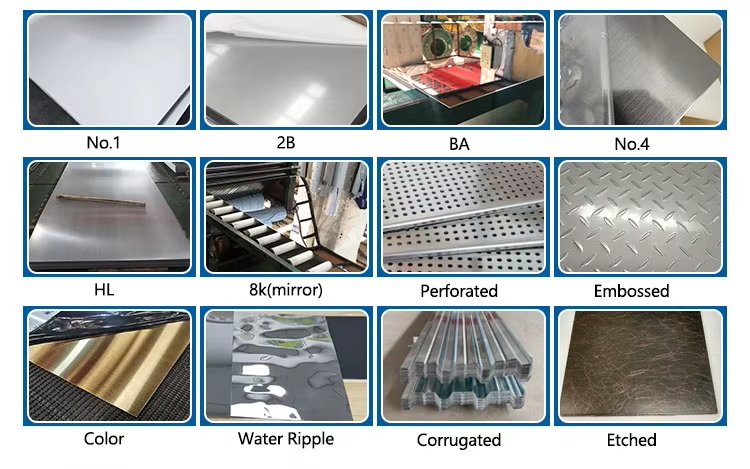

Comparison with Other Tube Finishes

It is important to understand how BA tubes differ from other stainless steel finishes:

BA vs Mill Finish: Mill finish tubes have a dull appearance and are not as clean or precise as BA tubes.

BA vs Polished Tubes: Polished tubes achieve a similar shiny surface through mechanical polishing, which may introduce surface contamination or scratches, unlike the clean finish of BA tubes.

BA vs Electropolished (EP) Tubes: EP tubes go through an additional process that removes a thin layer of metal for even higher purity and smoother surface. BA tubes are often a precursor to EP tubes.

Walmay help you to choose

Stainless steel BA tubes offer a compelling combination of visual appeal, structural integrity, and cleanliness that makes them indispensable in many demanding applications. Whether used in a sterile pharmaceutical plant or a sleek architectural installation, their superior finish and reliability deliver both performance and aesthetics. As industries continue to demand higher standards for hygiene and precision, the role of BA tubes will only become more prominent.

For manufacturers and engineers seeking materials that meet the highest standards of quality and cleanliness, stainless steel BA tubes remain an excellent choice.

If you have any inquiry, pls contact us freely sale@rylision.com. Whatsapp:+86 13026184819