Stainless Steel 201 vs 430: Which One Do You Like to Choose

- Emily

- Industry News

Choosing Between 201 and 430 Stainless Steel: A Buyer’s Guide to Properties & Costs

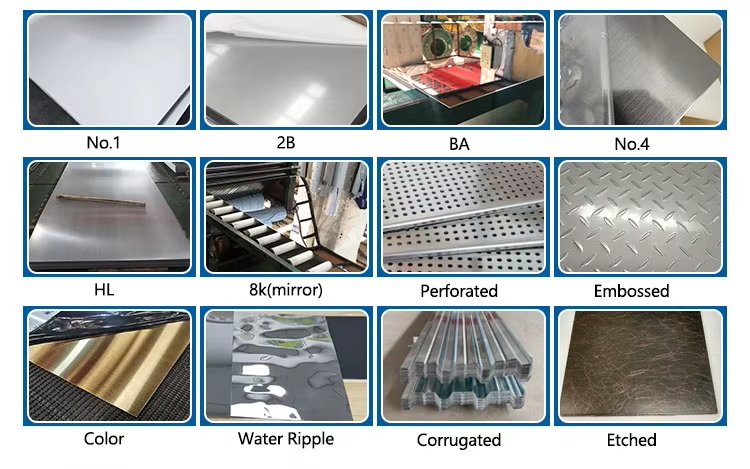

Stainless steel is one of the most versatile and widely used materials across many industries due to its corrosion resistance, durability, and aesthetic appeal. Among the various grades, 201 and 430 stainless steel are often compared because they are both cost-effective alternatives to the widely known 304 stainless steel. However, these two grades differ significantly in their chemical composition, mechanical properties, corrosion resistance, and typical applications.

This article provides an in-depth comparison of 201 and 430 stainless steel to help manufacturers, engineers, and buyers choose the right material for their specific applications.

1. Composition

201 Stainless Steel:

Part of the austenitic family (200 series).

Contains chromium (12.5-15%), nickel (1–2%), manganese (8–11%), and nitrogen (reduces nickel content).

Low carbon content (<0.15%).

430 Stainless Steel:

Part of the ferritic family (400 series).

Contains chromium (16-18%) but no nickel.

Higher carbon content (up to 0.12%) compared to 201.

The low nickel content in 430 results in reduced cost, but also affects its overall corrosion resistance and ductility compared to austenitic grades.

2. Corrosion Resistance

201 Stainless Steel provides moderate corrosion resistance. While it can resist oxidation and rust in many indoor and light industrial environments, it is not recommended for marine or highly acidic applications. It performs better than 430 in humid or mildly corrosive conditions.

430 Stainless Steel offers basic corrosion resistance, enough for dry indoor environments or decorative purposes. However, it is more prone to rusting in wet or salty conditions and is not suitable for environments where high corrosion resistance is essential.

If corrosion resistance is a priority, 201 is the better option between the two. For decorative or indoor use where exposure to moisture is limited, 430 may be sufficient.

3. Strength and Durability

201: Higher tensile strength and ductility due to its austenitic structure. Can be hardened by cold working.

430: Less ductile and more brittle (ferritic structure). Cannot be hardened by heat treatment.

4. Magnetic Properties

201 is generally non-magnetic in its annealed condition, but it can become slightly magnetic after cold working.

430 is strongly magnetic, even in its annealed form, due to its ferritic crystal structure.

This makes 430 suitable for applications where magnetism is needed (e.g., refrigerator panels, magnetic kitchen utensils).

5. Applications

201 Stainless Steel Typical Uses:

l Kitchen equipment (sinks, cookware)

l Food processing equipment

l Architectural trim and decoration

l Automotive trim

l Appliance exteriors

l Low-cost alternative to 304

430 Stainless Steel Typical Uses:

l Automotive exhaust systems

l Washing machine drums

l Dishwasher linings

l Refrigerator panels

l Fasteners and bolts

l Decorative trim in dry environments

6. Cost Considerations

201 typically costs 10-20% more than 430

Price fluctuates with nickel market prices

430 offers better value for non-corrosive applications

Total cost of ownership may favor 201 in corrosive environments

7. Maintenance and Longevity

201 requires less maintenance in harsh environments

430 may need protective coatings in outdoor applications

Both grades benefit from regular cleaning

201 maintains appearance longer in wet conditions

8. Environmental Resistance

Atmospheric Exposure:

201 performs better in coastal areas

430 shows surface rust in humid conditions

Chemical Resistance:

201 resists most household chemicals

430 degrades with strong acids/alkalis

Walmay help you to choose

When choosing between 201 and 430 stainless steel, the decision depends heavily on the application environment and required properties:

Choose 201 when you need a balance of strength, formability, and moderate corrosion resistance.

Choose 430 when cost is a primary factor and the environment is dry or decorative, with minimal exposure to corrosive agents.

By understanding the core differences, businesses and engineers can make informed material choices that optimize performance and cost-efficiency.

For any questions or to explore our product offerings, don’t hesitate to contact us sale@rylision.com. Whatsapp:+86 13026184819