316 vs 316L Stainless Steel:Which one is better to choose

- Emily

- Industry News

Differences Between Stainless Steel Grades 316 and 316L

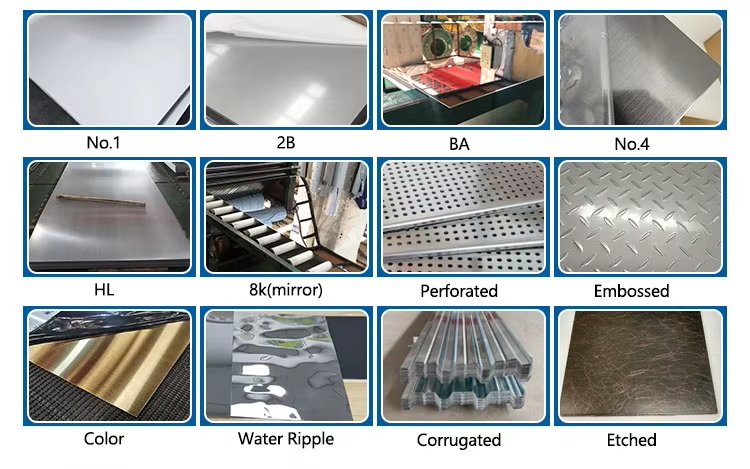

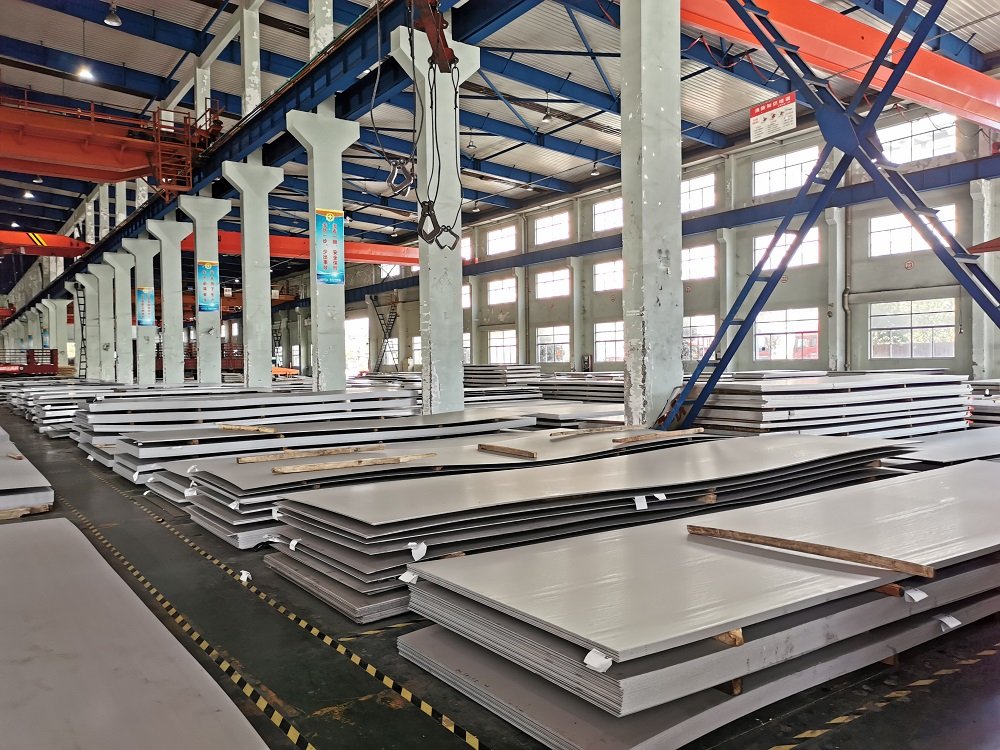

Stainless steel is a widely used material in various industries due to its excellent corrosion resistance, durability, and versatility. Among the many grades of stainless steel,such 201 steel, 304 steel, 316 and 316L are two of the most commonly used, particularly in environments where corrosion resistance is critical. While they share many similarities, there are key differences between these two grades that make them suitable for different applications.

What is the main difference of 316 vs 316l?

1. Chemical Composition

The primary difference between 316 and 316L stainless steel is the carbon content:

316 Stainless Steel contains a higher carbon content, typically up to 0.08%.

316L Stainless Steel (the “L” stands for low carbon) has a maximum carbon content of 0.03%.

This reduction in carbon content in 316L minimizes carbide precipitation during welding, which enhances its resistance to intergranular corrosion.

2. Corrosion Resistance

Both 316 and 316L offer excellent corrosion resistance, particularly in chloride-rich environments such as marine or chemical processing settings. However, the lower carbon content in 316L provides an additional advantage in certain conditions.

316 Stainless Steel: While 316 is highly resistant to corrosion, its higher carbon content makes it more susceptible to carbide precipitation when exposed to temperatures between 425°C and 860°C (797°F and 1580°F). This can lead to intergranular corrosion, especially in welded areas.

316L Stainless Steel: The reduced carbon content in 316L significantly lowers the risk of carbide precipitation, making it more resistant to intergranular corrosion, particularly in welded structures. This makes 316L the preferred choice for applications where welding is required or where the material will be exposed to corrosive environments over long periods.

3. Mechanical Properties

316 stainless steel has slightly higher strength and hardness compared to 316L due to its increased carbon content. However, 316L retains sufficient strength while offering better weldability and flexibility.

Property | 316 Stainless Steel | 316L Stainless Steel |

Carbon Content | ≤ 0.08% | ≤ 0.03% |

Yield Strength (MPa) | ~205 MPa | ~170 MPa |

Tensile Strength (MPa) | ~515 MPa | ~485 MPa |

Corrosion Resistance | High | Higher (for welding applications) |

Weldability | Good | Excellent |

4. Applications

The differences in composition and properties between 316 and 316L make each grade suitable for specific applications.

316 Stainless Steel: Due to its higher strength and better performance at high temperatures, 316 is often used in applications such as heat exchangers, furnace parts, and chemical processing equipment that operates at elevated temperatures.

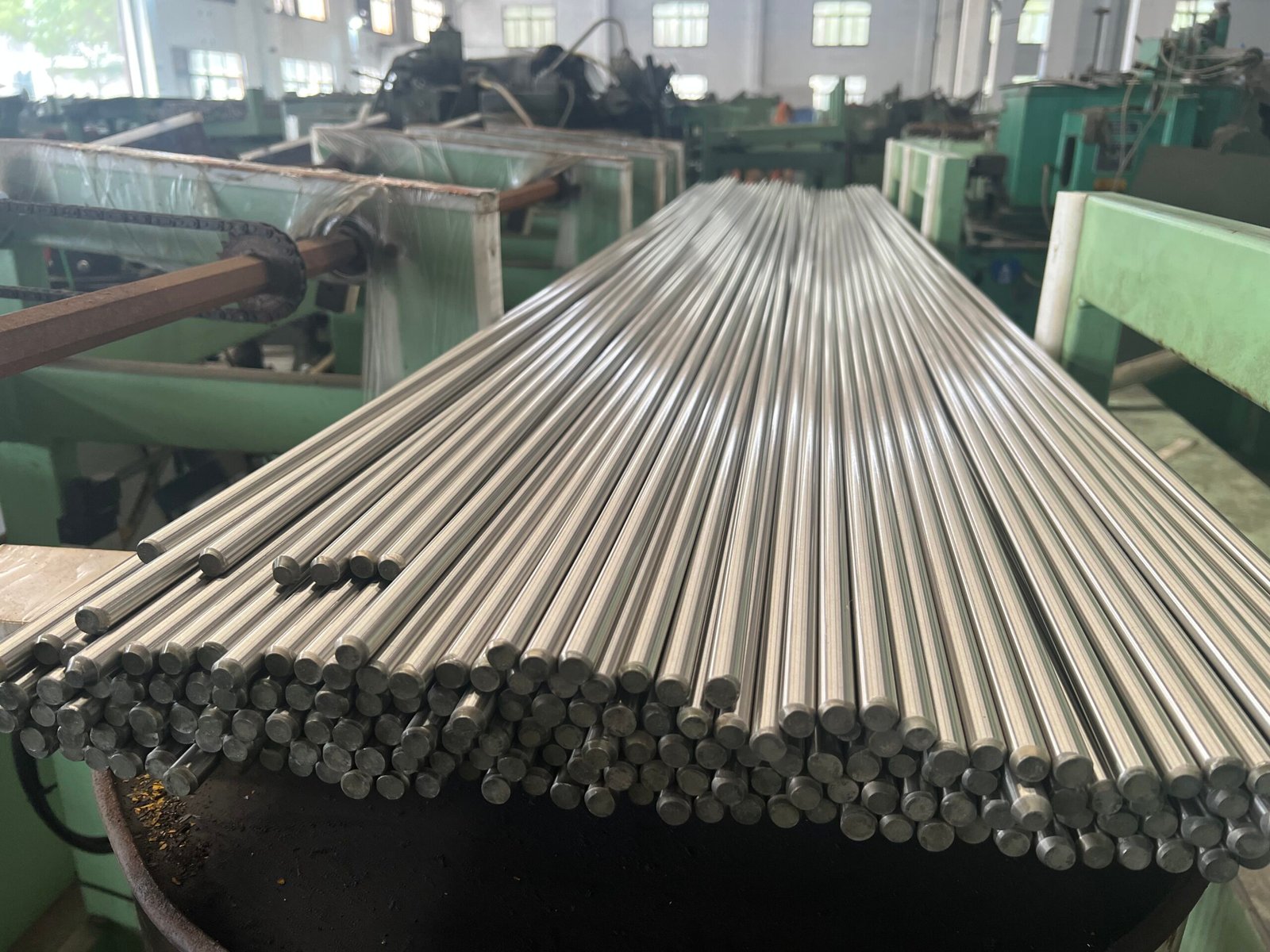

316L Stainless Steel: The superior weldability and resistance to intergranular corrosion make 316L the preferred choice for applications involving welding or exposure to corrosive environments. Common uses include pharmaceutical equipment, marine components, and surgical instruments.

5. Cost Considerations

In terms of cost, 316 and 316L are generally similar, but the choice between the two may depend on the specific requirements of the application. While 316L may be slightly more expensive due to its enhanced corrosion resistance and weldability, the long-term benefits in terms of durability and reduced maintenance often justify the additional cost.

Walmay help you to choose

Both 316 and 316L stainless steel offer exceptional corrosion resistance and mechanical properties. The choice between the two depends on the specific application requirements, particularly in terms of welding needs and exposure to corrosive environments. If welding is involved or reduced carbon content is necessary, 316L is the better choice. Otherwise, 316 may be preferable for its slightly higher mechanical strength.

If you have any inquiry, pls contact us freely sale@rylision.com. Whatsapp:+86 13026184819