316 Stainless Steel Bar

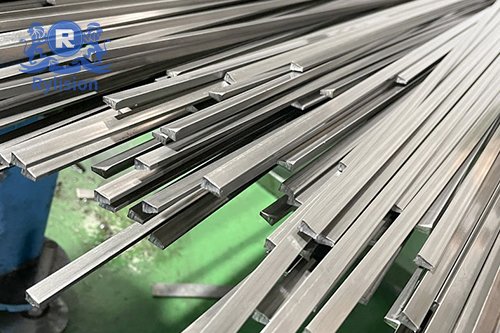

Stainless steel bar is the most essential players in the machining industry. Stainless steel bars applications and utilizations rely on the kind of required and come in different forms as well, such as flat bars, round bars, hexagonal bars, square bars. This is why stainless steel bars are chosen to create machine parts and automotive components.

- Products Description

- Chemical Analysis

- Product Inspection

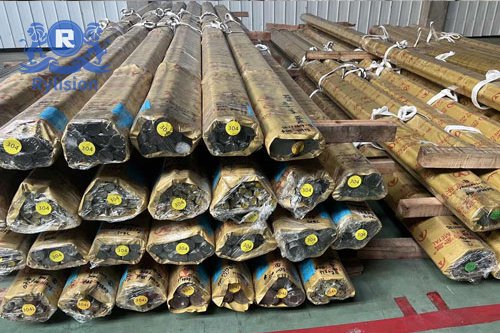

- Product Packaging

Product Description

| Product Name | Stainless Steel Bar |

| Technique | Cold Rolled; Hot Rolled |

| Shape | Round, Square, Hexagonal |

| Material | 200 series,300 series,400 series,900 series |

| 201,202,304,304L,316,316L,321,310S,403,410,416,420,430,940L. etc | |

| Standard | JIS/SUS/GB/DIN/ASTM/AISI/EN/BS |

| Surface | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Package | clients’ requirement and Standard export sea-worthy packing |

| MOQ | 1 ton |

| Product Name | AISI | ASTM | JIS | BS | DIN | W. Nr |

| Flat Bar, Angle Bar | 304 | S30400 | – | – | – | – |

| 316L | S31603 | – | – | – | – | |

| Hot Rolled Bar Peeled Round Bar Cold Drawn Round Bar Cold Drawn Square Bar Cold Drawn Hexagon Bar Centreless Grinding Round Bar | ||||||

| 304 | S30400 | SUS304 | BS304S31 | X5CrNi1810 | 1.4301 | |

| 304N | S30451 | SUS304N1 | – | – | – | |

| 304L | S30403 | SUS304L | BS304S11 | X2CrNi1911 | 1.4307 | |

| 304LN | S30453 | SUS304LN | – | X2CrNiN1810 | 1.4311 | |

| 316 | S31600 | SUS316 | BS316S31 | X5CrNiMo17122 | 1.4401 | |

| 316N | S31651 | SUS316N | – | – | – | |

| 316L | S31603 | SUS316L | BS316S11 | X2CrNiMo17132 | 1.4404 | |

| 316LN | S31653 | SUS316LN | – | X2CrNiMoN17122 | 1.4406 | |

| 430 | S43000 | SUS430 | BS430S17 | X6Cr17 | 1.4016 | |

| 430F | S43020 | SUS430F | – | X7CrMoS18 | 1.4105 | |

| 403 | S40300 | SUS403 | – | – | – | |

| 410 | S41000 | SUS410 | BS410S21 | X10Cr13 | 1.4006 | |

| 416 | S41600 | SUS416 | BS416S21 | – | 1.4005 | |

|  |  |

|  |  |

Chemical Analysis

| UNS | ASTM | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| S20100 | 201 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0.06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | – |

| S20200 | 202 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0.06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | – |

| S30100 | 301 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | – |

| S30400 | 304 | 1.4301 | SUS304 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | – |

| S30403 | 304L | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-12.0 | – |

| S30908 | 309S | 1.4833 | SUS309S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | – |

| S31008 | 310S | 1.4845 | SUS310S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.50 | 24.0-26.0 | 19.0-22.0 | – |

| S31600 | 316 | 1.4401 | SUS316 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31603 | 316L | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31703 | 317L | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| S32100 | 321 | 1.4541 | SUS321 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | – |

| S34700 | 347 | 1.455 | SUS347 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | – |

| S40500 | 405 | 1.4002 | SUS405 | ≤0.08 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0.60 | – |

| S40900 | 409 | 1.4512 | SUS409 | ≤0.08 | ≤1.00 | ≤0.045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0.50 | – |

| S43000 | 430 | 1.4016 | SUS430 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤0.75 | 16.0-18.0 | ≤0.60 | – |

| S43400 | 434 | 1.4113 | SUS434 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | – |

| S44400 | 444 | 1.4521 | SUS444L | ≤0.025 | ≤1.00 | ≤0.045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | – |

| S40300 | 403 | – | SUS403 | ≤0.15 | 5.5-7.5 | ≤0.04 | ≤0.03 | ≤0.50 | 11.5-13.0 | ≤0.60 | – |

| S410000 | 410 | 1.40006 | SUS410 | ≤0.15 | ≤1.00 | ≤0.035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0.60 | ≤1.00 |

| S42000 | 420 | 1.4021 | SUS420J1 | 0.16~0.25 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0.75 | ≤1.00 |

| S440A | 440A | 1.4028 | SUS440A | 0.60~0.75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | ≤0.75 |

| S32750 | SAD2507 | 1.441 | ≤0.03 | ≤1.2 | ≤0.035 | ≤0.02 | ≤0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | |

| S31803 | SAF2205 | 1.4462 | ≤0.03 | ≤2.0 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 | |

| N08904 | 904L | 1.4539 | ≤0.0.3 | ≤2.0 | ≤0.035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0-4.0 |

Rylision offer comprehensive product inspection services to ensure the highest quality standards. Our team conducts thorough checks on each product, verifying dimensions, finish, and strength, so our customers receive reliable and precise stainless steel and aluminum products that meet their exact requirements.

|  |  |

|  |  |