201 vs 304 Stainless Steel? A Buyer’s Guide for Durability & Savings

- Emily

- Industry News

304 vs 201 Stainless Steel: Which Grade Should You Choose

When choosing stainless steel for industrial or consumer applications, two common options are 201 and 304 stainless steel. While both belong to the austenitic family of stainless steels, they have distinct differences in terms of composition, corrosion resistance, mechanical properties, and applications. This article outlines the key comparisons to help you make an informed decision.

1. Chemical Composition

The primary difference between 201 and 304 stainless steel lies in their alloy content, which affects performance.

Element | 201 Stainless Steel | 304 Stainless Steel |

Chromium (Cr) | 16-18% | 18-20% |

Nickel (Ni) | 3.5-5.5% | 8-10.5% |

Manganese (Mn) | 5.5-7.5% | ≤2% |

Carbon (C) | ≤0.15% | ≤0.08% |

Nitrogen (N) | Added for strength | Minimal |

The higher nickel content in 304 provides better corrosion resistance, while 201 relies more on manganese and nitrogen as cost-effective substitutes for nickel.

2. Corrosion Resistance

304 stainless steel offers excellent corrosion resistance, making it suitable for marine environments, food processing, and chemical equipment.

201 stainless steel provides moderate corrosion resistance, which is acceptable for indoor use or low-exposure environments. It may rust or discolor in humid or salty conditions.

3. Strength & Formability

201 Stainless Steel

- Higher strength due to manganese and nitrogen.

- Less ductile, making it harder to form or weld.

- More prone to cracking under stress.

304 Stainless Steel

- More ductile and easier to weld/fabricate.

- Better for deep drawing, bending, and machining.

- Maintains strength at high temperatures.

Winner: 304 stainless steel for better workability and versatility.

4.Magnetic Properties

201 Stainless Steel: Slightly magnetic (due to manganese).

304 Stainless Steel: Generally non-magnetic (may become slightly magnetic after cold working).

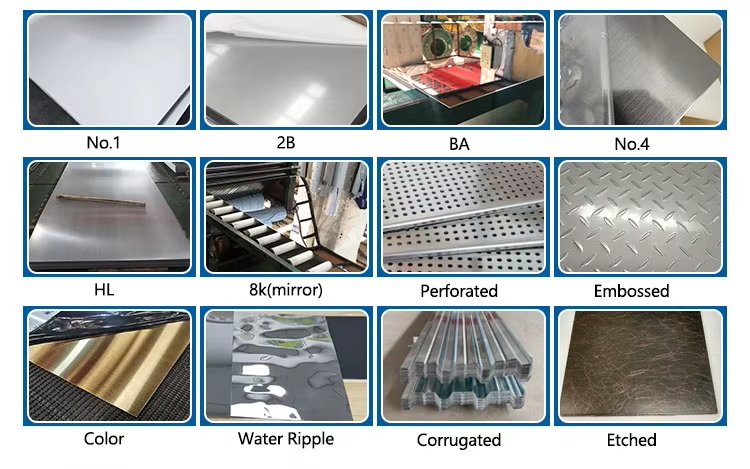

5. Applications

201 Stainless Steel:

- Household appliances

- Cookware (inner components)

- Automotive trim

- Furniture and decorative elements

304 Stainless Steel:

- Kitchen equipment and sinks

- Food and beverage processing

- Chemical containers

- Medical and marine applications

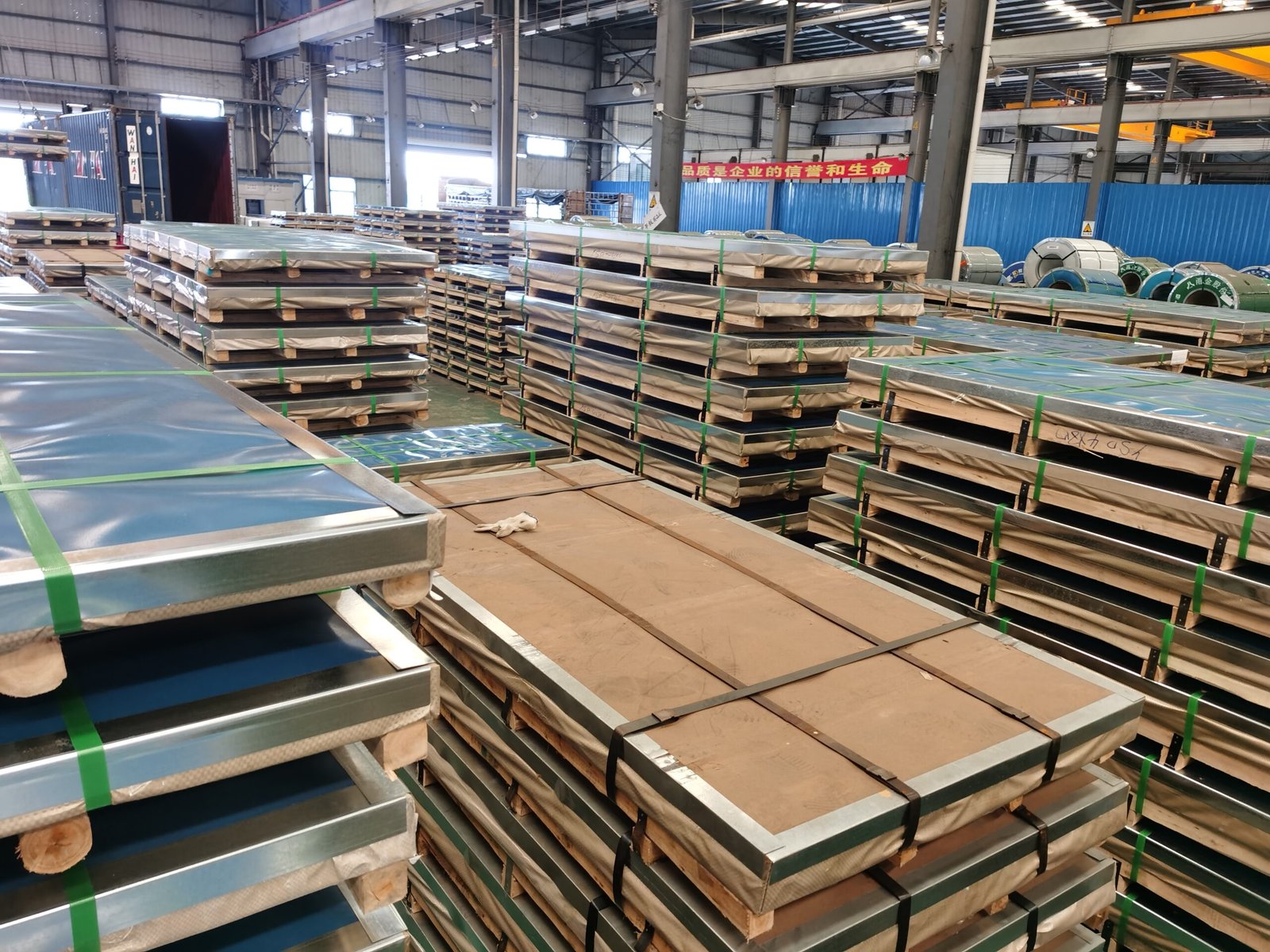

6. Cost Comparison

201 Stainless Steel is cheaper (due to lower nickel content).

304 Stainless Steel is more expensive but offers better longevity.

Best Choice:

Budget-friendly option → 201

Long-term investment → 304

Walmay help you to choose: Which One Should You Choose?

Choose 201 Stainless Steel If:

- You need a low-cost option for indoor applications.

- The environment is not highly corrosive.

- Higher strength is needed, but formability is less critical.

Choose 304 Stainless Steel If:

- You require superior corrosion resistance(outdoor, marine, or industrial use).

- Better weldability and formabilityare needed.

- Long-term durability justifies the higher cost.

Final Verdict:

|

Factor |

201 Stainless Steel |

304 Stainless Steel |

|

Corrosion Resistance |

Moderate |

Excellent |

|

Strength |

Higher |

More Ductile |

|

Cost |

Lower |

Higher |

|

Best For |

Indoor, budget uses |

Harsh environments, high durability |

For most industrial and outdoor applications, 304 stainless steel is the better choice. However, 201 is a cost-effective alternative for less demanding uses.

If you have any inquiry, pls contact us freely sale@rylision.com. Whatsapp:+86 13026184819